Manufacturing managers in charge of the downstream processing plant for synthetic or recombinant peptides know very well that CIP of a packed chromatography column is a “necessary evil” to extend the lifetime of the bed. While CIP is a step that one may want to avoid as much as possible, it is also an economically important practice that can reduce the cost of manufacturing your API.

Considerations for performing CIP on columns packed with a bonded phase silica gel

The first and primary consideration is the CIP agent–what chemical to use. Of course, a milder chemical with pH closer to neutral is always preferred. However, mild agents will not generally be effective to remove contaminants that are bound tightly to your bonded phase. Washing with organic solvent may also be helpful to remove certain hydrophobic species, but solvent alone will not result in a deep CIP of the column.

If the “mild” chemical and “simple” solvent-only options fail to do adequate cleaning and restoration of column performance, the last resort is usually aqueous NaOH solution in the presence of organic solvent.

For the NaOH-based CIP, we recommend the following:

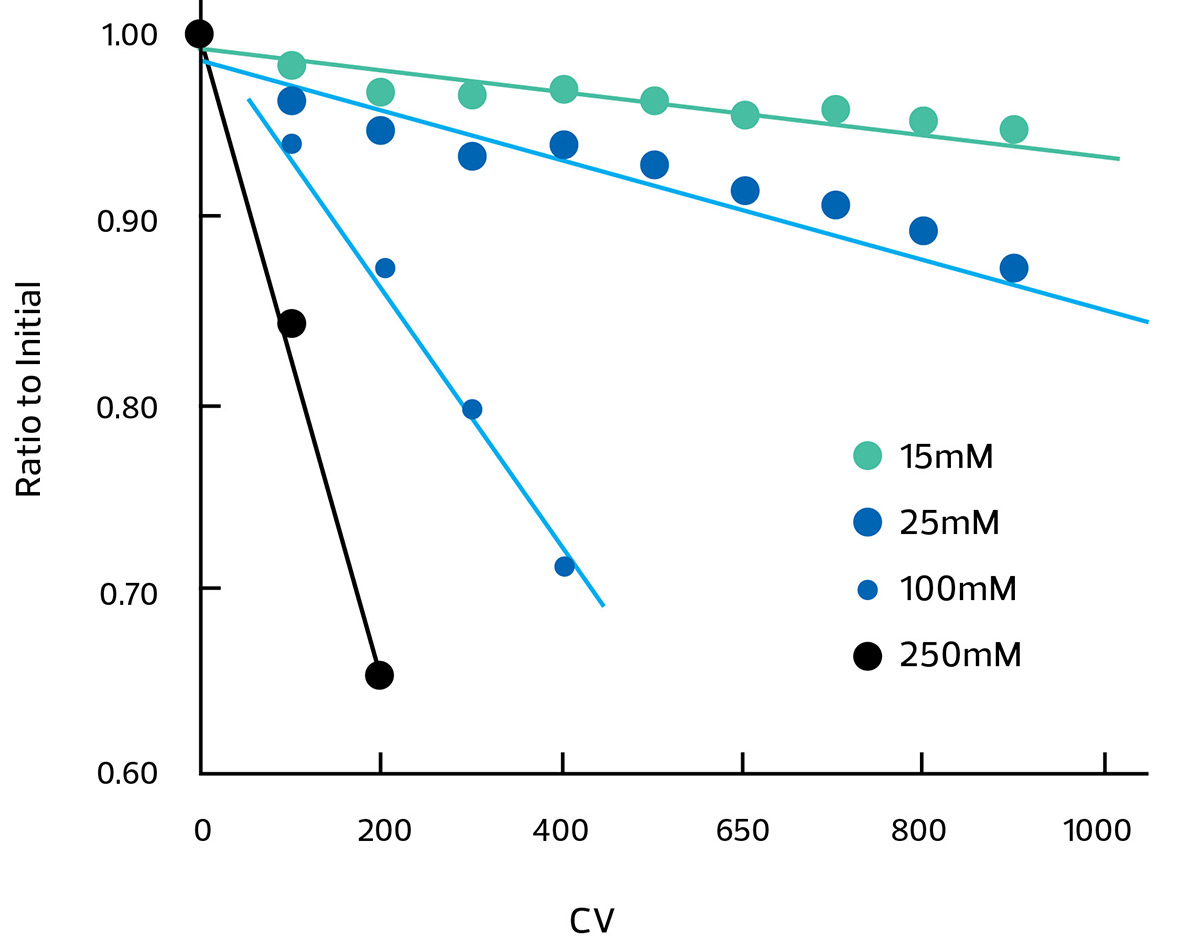

- Use as low of NaOH concentration as possible which still does an adequate cleaning. Higher NaOH concentrations will more quickly reduce retention time of your column due to loss of bonded ligands

Retention Time for Naphthalene

Effect of different NaOH concentration on how quickly the column retention time shortens due to loss of bonded ligands.

- Run the NaOH CIP as infrequently as possible while still restoring column performance

- Similarly, only initiate the first caustic CIP after as many purification cycles have been run while still maintaining acceptable column performance. There may be no need to run your initial CIP until after purification number cycle number five (or even until cycle ten if your SOP calls for CIP after every five cycles)

- Don’t base your CIP method on the volume of NaOH solution you intend to pass over the column; instead, base the cleaning on the contact time of the silica with the NaOH solution

- After CIP with NaOH, IMMEDIATELY neutralize the column by washing the bed with an appropriately acidic pH solution

- Perform the CIP step in backflush/reverse flow mode!

Contact us to learn more

For further ideas to evaluate your CIP process, please contact us!