Once you scale up your process beyond semi-prep or preparative prepacked columns, you will need to pack our bulk silica gel in a dynamic axial compression (DAC) column. Here, we provide a procedure for packing, testing, and unpacking one of our most prominent silica gels: the C8-PK Series with 10 µm particle size (Product Name SP-100-10-C8-PK).

Calculate the Necessary Silica Gel and Volume Required

The first step is to determine the amount of silica gel and slurry solvent required to pack your column. You can do that by using these simple calculations:

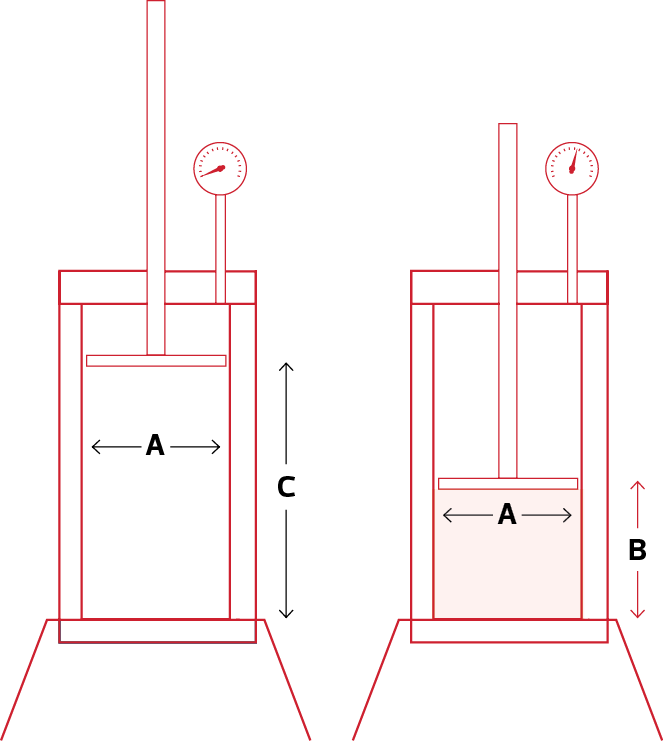

- Start with the dimensions of your empty column and your target packed bed:

A mm I.D. x C mm L (inner diameter x total empty column length)

A mm I.D. x B mm L (inner diameter x target bed length) - Determine the column’s total capacity for slurry as well as the target packed bed volume:

Total column capacity (ml) = (A/2)2 x π x (C/1000)

Packed column capacity (ml) = (A/2)2 x π x (B/1000) - Calculate the necessary stationary phase mass:

Silica amount (gram) = packed column capacity (ml) x silica density (g/ml)

The density of SP-100-10-C8-PK is 0.58 g/ml.

For packing densities of other DAISOGEL phases, check here.

Knowing the column’s total capacity for slurry, as well as the amount of silica required to achieve the desired bed length, you can now prepare the slurry.

Slurry Preparation

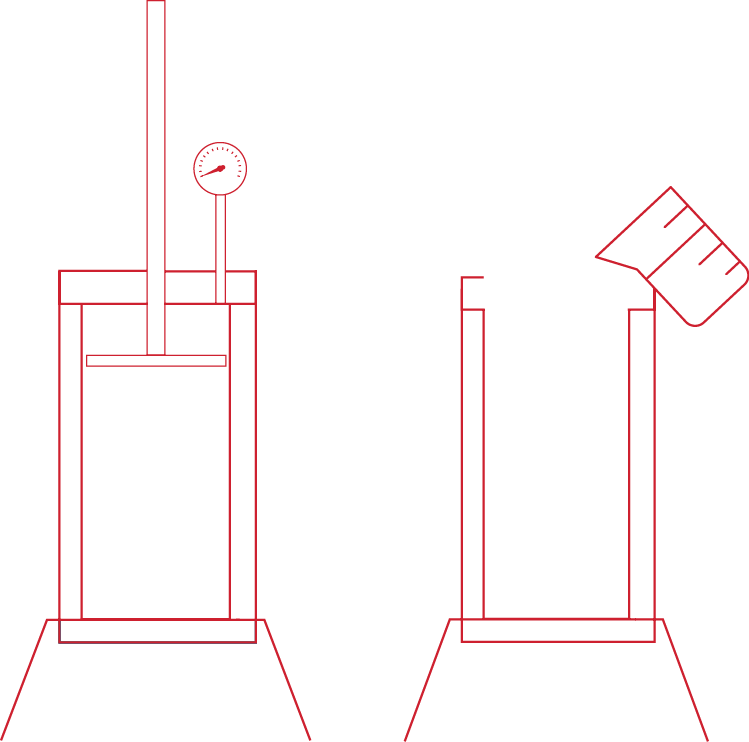

Weigh out the appropriate amount of silica gel in grams as calculated above. While you should prepare at least a 50% slurry by weight, we highly recommend a thinner slurry for best packing results: 3 parts slurry solvent for 1 part silica gel.

To illustrate, for SP-100-10-C8-PK, we recommend 600 ml of 2-propanol and 200 g of bulk C8-PK silica gel for a 50 mm I.D. x 200 mm L bed. However, you must ensure that your total slurry volume does not exceed the total column capacity as calculated above. Otherwise you may need to adjust the 3:1 ratio downward to ensure you don’t overfill the empty column with slurry.

For smaller-volume slurry preparations of less than 5 liters, the slurry can be prepared in a beaker or carboy. Always take precautions when handling dry silica gel and organic solvents! Recommended PPE includes a proper breathing mask, safety glasses, and gloves.

1 PART

SILICA GEL

3 PARTS

SLURRY SOLVENT

MIX SOLUTION

THOROUGHLY

Silica gel is a fine powder that flows free and can easily become airborne. It is considered carcinogenic, so handle with care. Avoid contact with skin and eyes, and do not inhale.

Prepare the slurry in a well-ventilated area, ideally under a fume hood. This helps to capture any airborne dry silica powder and exhaust the solvent fumes. Always follow the safety guidelines set out by your company’s safety policy!

Smaller volumes can be easily mixed by hand with a small paddle. Handle the silica gently! Even mechanically robust particles such as DAISOGEL may crack when pressed too hard. Avoid using metal spatulas with sharp edges or metal shovels. Plastic stirrers or paddles are appropriate. Ensure a homogenous slurry by mixing the silica gel and slurry solvent well.

When packing larger DAC columns of 30 cm I.D. and higher, a larger slurry volume is required. You will require a larger container to prepare the slurry. Follow the same 3:1 ratio of 2 -propanol to silica gel. Follow the same safety precautions as you would for the smaller volume slurry prep, but also keep in mind that your site may have additional safety precautions when handling larger volumes of silica gel and solvent. Please check with your safety officer. While mixing of larger volumes can be done manually with a paddle, you can also consider gentle air-driven mixers to assist with large slurry volumes. Some DAC column suppliers also offer slurry preparation systems that include tanks and mixers. We suggest that you follow the recommendation of your DAC column device manufacturer.

A Note About Defining

Many silica gels with wide particle size distribution also require defining at this stage in order to remove small, fine particles that may cause excess backpressure in the packed column.

In a typical defining process, you let the silica gel “settle” in the beaker or tank for 15-30 minutes after mixing, and then decant any fines from the cloudy supernatant solvent layer at the top of the vessel. While this is best practice with many silica gels –especially those with large particle sizes or irregular beads–defining is not required with the initial packing of C8-PK Series due to its monodispersity. However, after unpacking and prior to repacking, we recommend defining your C8-PK Series spent phase twice.

If very through cleaning of spent phase is needed, re-slurrying the gel and stirring in a reactor is the best, followed by filtration.

Packing the DAC Column

With the slurry prepared, you are ready to pack the column. Fill the empty column with the slurry according to the instructions of the column manufacturer.

To achieve the best packing, do not let the silica gel settle in the slurry prior to transferring it into the column. Once you have filled the column with slurry, you should begin the packing as soon as possible to avoid settling (within a minute or two).

Axially compress the slurry into a packed bed according to the column manufacturer instructions.

As always, wear safety eyewear and appropriate PPE! SP-100-10-C8-PK should be packed at piston pressures of at least 70 bar and up to 100 bar. Check for leakage during the packing process, and if leakage is found, please refer to your column device instructions. Confirm that the bed length is as expected.

How to Confirm Column Efficiency

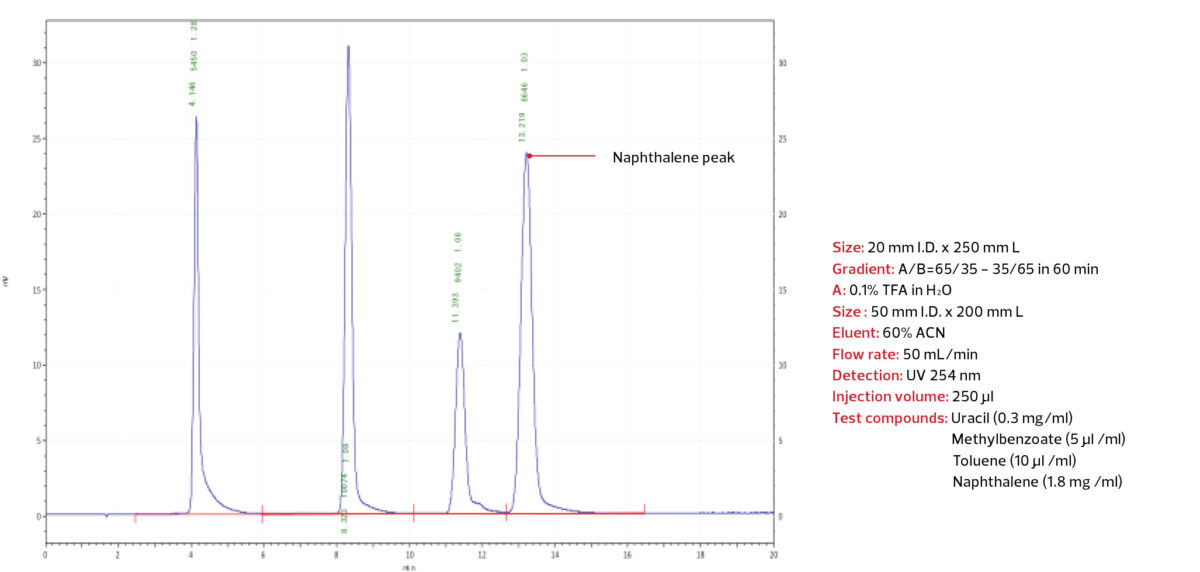

Now that your DAC column is packed, you should test its performance prior to purifying your API. Column efficiency is tested through a sample test injection. For SP-100-10-C8-PK, test compounds such as naphthalene and toluene can be used, as they have good UV absorbance and will also have some retention on the column. Two efficiency calculations are typically run.

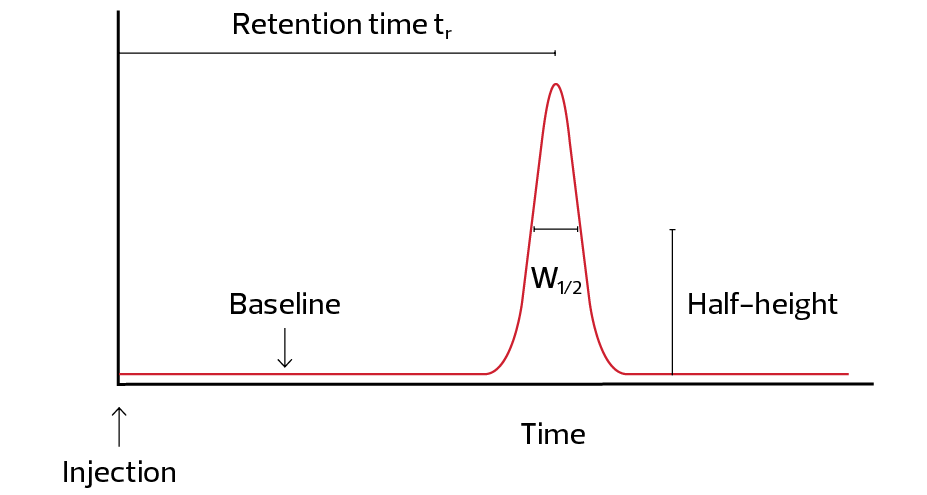

The number of theoretical plates (N) of the packed column describes its separation efficiency and is calculated using the following formula:

N = 5.54 x (tr)2/ (w½)2

N = number of theoretical plates

tr= retention time

w½ = peak width at half-height

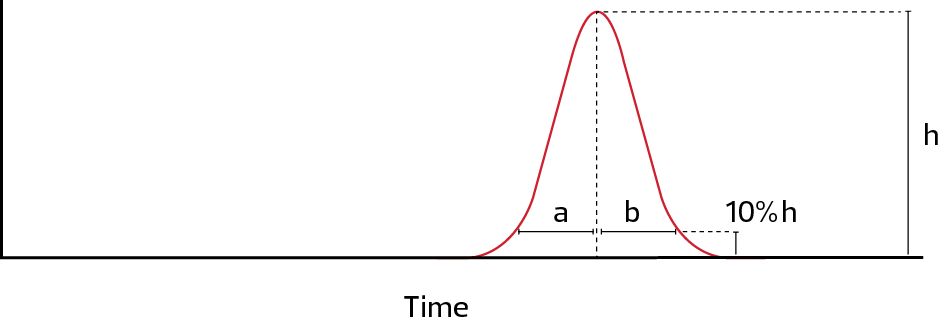

The second calculation is peak asymmetry, which informs the peak shape quality of the eluted test compound; a Gaussian peak shape is indicative of a well-packed column. Asymmetry is calculated using the following formula:

As = b/a

As = peak asymmetry

b = right half of peak width at 10% peak height

a = left half of peak width at 10% peak height

The column passes the efficiency tests if the number of theoretical plates N is greater than 35,000 plates per meter and the peak asymmetry is between 0.8 and 1.2 for the test compound peak.

Example Efficiency Test Conditions for 50 mm I.D. DAC Column:

- Slurry 200 g of SP-100-10-C8-PK with 600 ml of 2-propanol, transfer the slurry into the empty column, and pack at 100 bar. This will result in a bed height of approximately 20 cm.

- Equilibrate the column with 60% methanol or acetonitrile at 50 ml/min for 4 to 5 column volumes.

- Prepare a 250 μl test injection sample in 70% methanol. We recommend naphthalene at 1.8 mg/ml or toluene at 10 μl/ml.

- Ensure that the injection is performed as close to the head of the column as possible with minimized dead volume. Also ensure that the UV flowcell is as close to the outlet of the column as possible with minimized dead volume.

- After injection, elute with 60% methanol or acetonitrile at 50 ml/min until the peak(s) appear.

- Measure N and As either through your data acquisition software or through pencil and ruler measurement on the chromatogram print out.

Column Efficiency Test With a Mixture of Test Compounds

Unpacking the DAC Column and Storing the Silica Gel

Unpacking conditions depend on how you want to store the silica. If you wish to store the unpacked silica dry, the recommended procedure is to flush the packed column with at least 4 CVs of a highly volatile solvent (MeOH or ACN) after the silica has been properly washed with water (if salt removal is necessary). Follow the DAC column device manufacturer’s unpacking instructions.

For dry silica storage, you can evaporate the solvent from the unpacked silica gel by evenly spreading the wet cake on a wide plate in about 70°C condition–if possible under laminar flow hood. Store the dry silica gel in a low humidity location in covered bottles at room temperature.

If you wish to store the unpacked silica wet, the recommended procedure is to flush the packed column with at least 4 CVs of the slurry solvent (2-propanol). Again, follow the DAC column device manufacturer’s unpacking instructions. Store the unpacked wet silica in the slurry solvent (2-propanol) in a closed container at room temperature.

Do you need assistance packing your column?

Reach out for support from our DAISOGEL packing experts.